2020.04.13

On April 10th and 11th, three skill PK competitions were held in the first line of the JP cabinet of the company's box substation workshop, the 10kV brace curtain in the fourth workshop, and the welding of 110kV clamps in the first workshop.

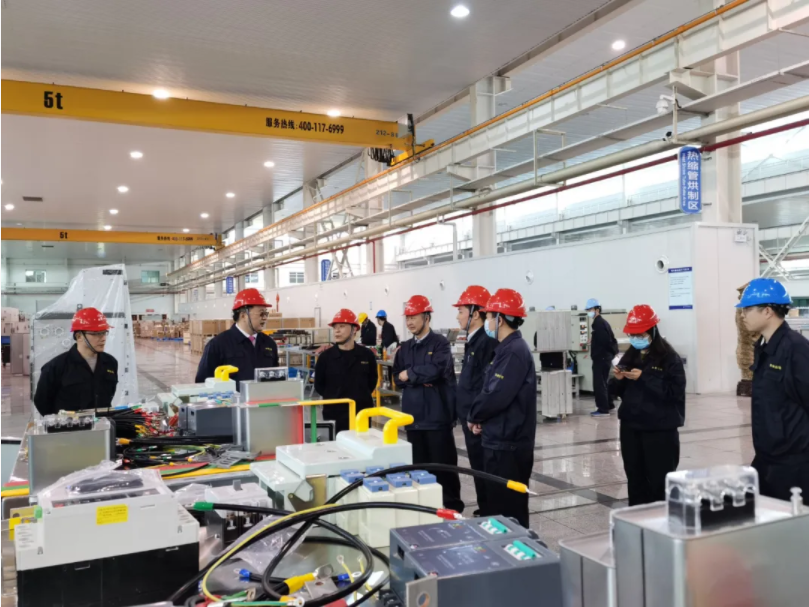

Mr. Shen visited the box-transformer workshop and deployed the process and material preparation for the installation of the box. It requires everyone to arrange the process reasonably, use resources reasonably, improve efficiency, and improve quality.

On April 10th, the box-transformation workshop took the lead in carrying out a JP-100 installation PK competition, which took the form of seven single-person combinations, each with 12 sets of tasks. This workload was time-consuming according to previous statistics and requires 18 It takes hours to complete, that is, it takes more than two days of work. This time, it is a big challenge to arrange the game to be completed at one time. In order to make this competition a complete success, the workshop did a lot of preparation work in advance, such as the production of copper bars, the prefabrication of connecting wires, the unpacking of various electrical components, the inventory of quantities, and the quality inspection.

After the hard work of seven employees, the fastest was completed at 9:00 in the evening and the slowest ended at 11:00 in the evening. The efficiency has been greatly improved in the past.

In the two games conducted on April 11, the content of the four workshops was to paste the insulation group SBH15-M-200/10 bracing curtains in a single group of 4 groups, each with a task of 20 units. According to the past production efficiency, only 10 workloads can be pasted per person and one shift. In this PK, workshop leaders and the production department made more careful planning and arrangements to make the preparation of various materials for the competition adequate. In accordance with the requirements of the PK master plan, the workshop conducted process training and assessment for the participating employees, so that everyone can fully understand the basic knowledge and manufacturing process of insulation parts, so that they can completely achieve strict "three-press production" in operation.

The 110kV clip welding competition in the first workshop is the company's first self-competition, that is, the PK between its current efficiency and its past efficiency. The production of large clips has been in short supply for a long time, which has affected the next iron core lamination process. At the same time, the workshop produces it by itself. Due to the low efficiency, high cost, and lack of market competitiveness, the production department has been so troubled by this, often I need to find a supplier that meets the requirements of our company. I once wanted to remove this process. A full set of clips are prepared for outsourcing and personnel are diverted. However, the employees of Wubian Company have a spirit of unsuccessful defeat. The workshop director actively asked the superiors to retain this process. On the premise that the leaders of the production department and the workshop reached consensus, the two parties made careful planning and organization. After the self-PK competition, the efficiency of the participating employees improved significantly, and the efficiency of a single unit increased by 29%.

Next, the company will also hold a variety of skill competitions. Through these competitions, I hope that the workshop will carefully review the experience and lessons, sum up certain rules, improve the efficiency and quality of work, and continue in the future work Work hard to achieve Wu's goal of becoming a leader in the power transmission and transformation industry.